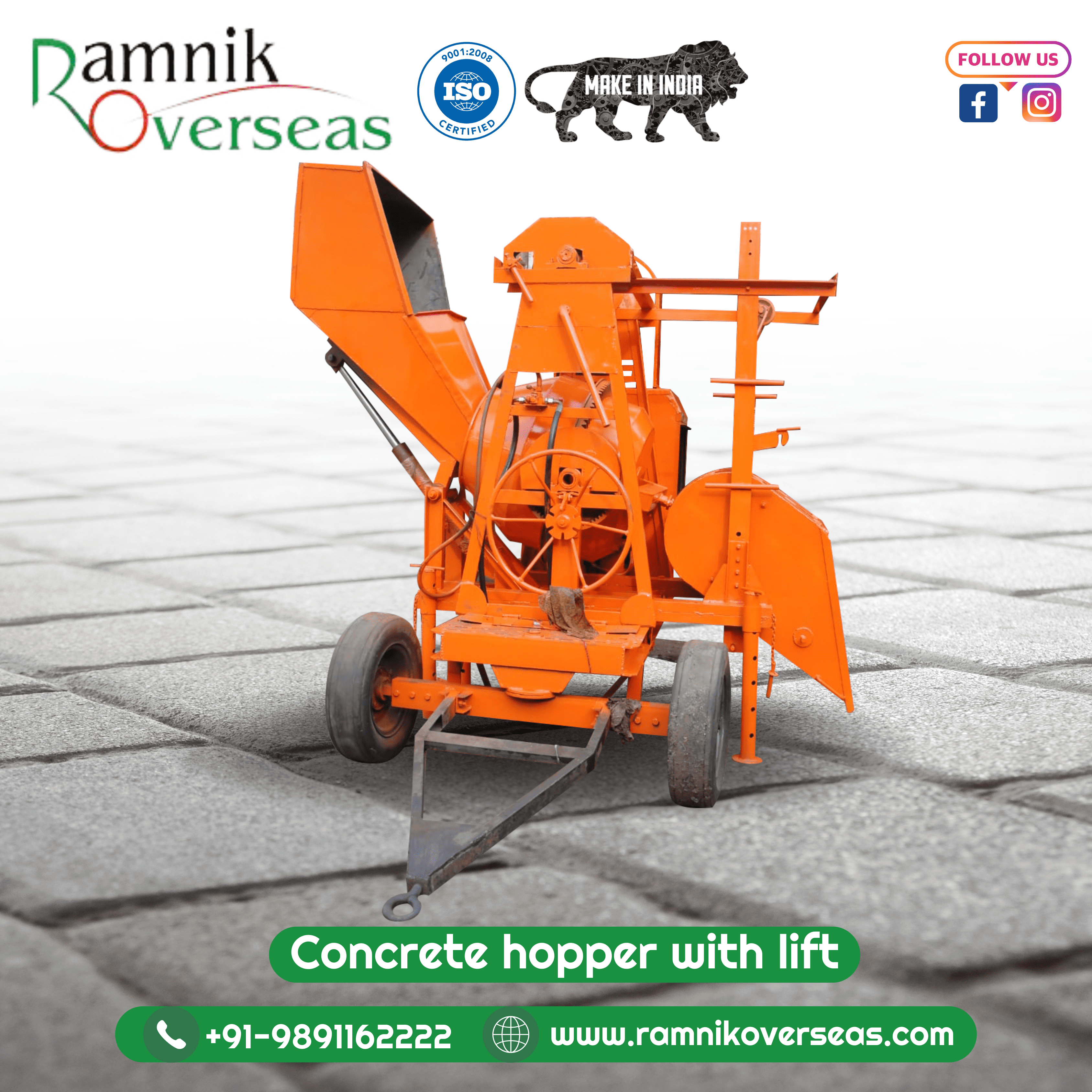

An interlocking tiles making machine is a device used to manufacture interlocking tiles, which are commonly used in paving driveways, walkways, patios, and other outdoor surfaces. These machines typically consist of various components such as molds, hydraulic systems, mixing chambers, and vibrating tables.

Mixing: The machine starts by mixing raw materials such as cement, sand, aggregates, and color pigments in a designated mixing chamber. This mixture forms the base material for the tiles.

Molding: Once the materials are thoroughly mixed, they are poured into molds that are designed to create the desired shape and size of the interlocking tiles. The molds are typically made of metal or plastic and come in various shapes and sizes depending on the specific design of the tiles.

Pressing: After the molds are filled, hydraulic systems within the machine apply pressure to compact the mixture and ensure that the tiles are formed with the desired strength and density.