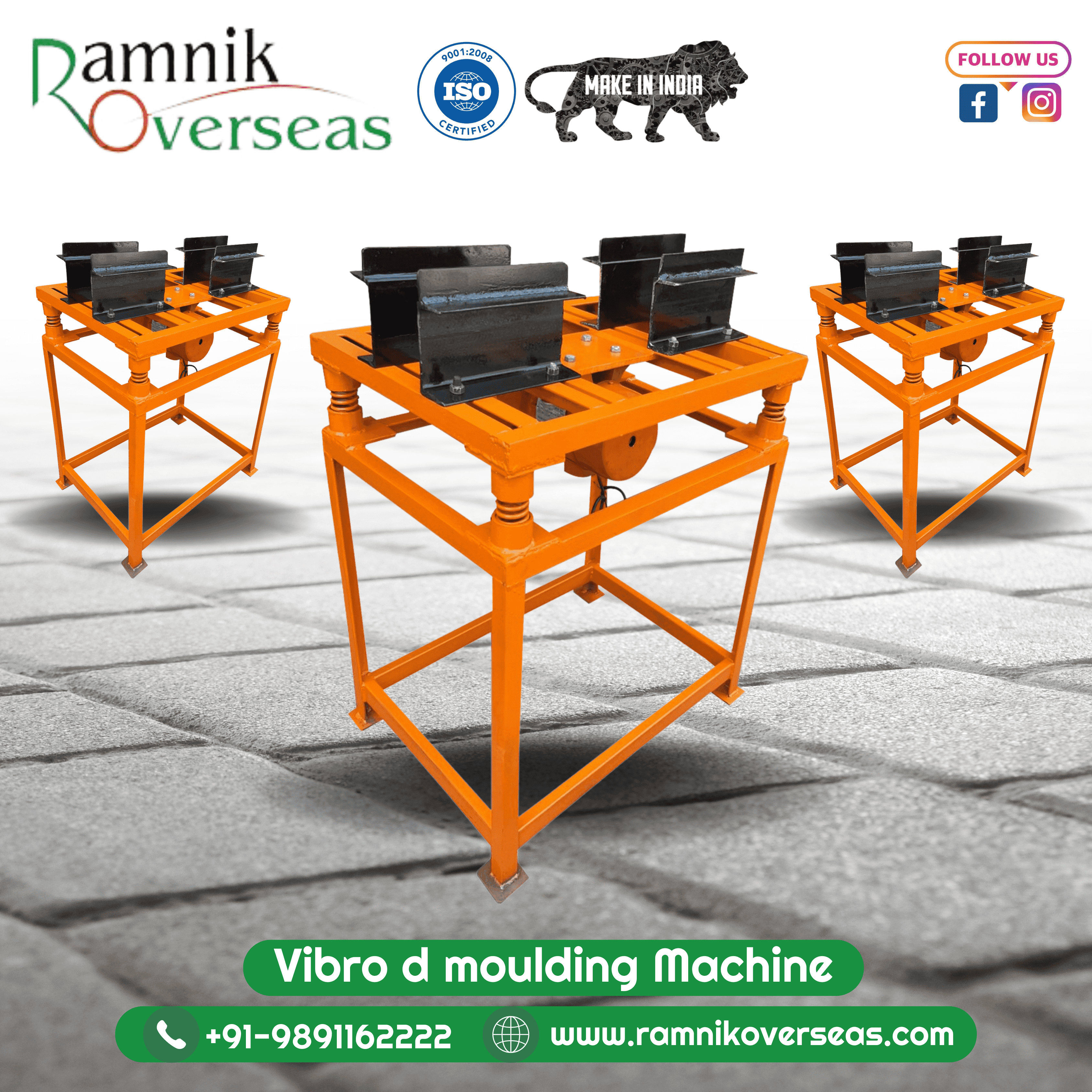

Vibro D Moulding Machine: Enhancing Efficiency and Precision

The Vibro D Moulding Machine is a state-of-the-art equipment designed to streamline the process of moulding in various industries. With its advanced technology and innovative features, it has become an indispensable tool for manufacturers seeking to enhance efficiency and precision in their production processes.

Benefits of Vibro D Moulding Machine

Improved Productivity: The Vibro D Moulding Machine significantly improves productivity by automating the moulding process. It eliminates the need for manual labor, reducing the time required for each operation and increasing output.

Enhanced Precision: With its advanced controls and precision engineering, the Vibro D Moulding Machine ensures consistent and accurate moulding results. It eliminates human errors and delivers high-quality finished products.

Cost Savings: By automating the moulding process, the Vibro D Moulding Machine reduces labor costs and minimizes material wastage. It optimizes resource utilization and improves overall cost-efficiency.